2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

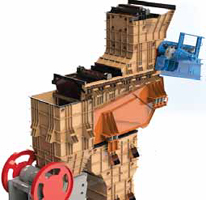

Weba Chute Systems reported a recent solution deployed to a diamond mine in Botswana solved maintenance challenges and ensured more uptime for the customer’s operation. The mine was replacing transfer chutes almost every three months. Run-of-mine material, with lump sizes up to 1,200 mm, is fed via an apron feeder onto a grizzly feeder, with the oversize material reporting to the jaw crusher. Larger particles of lump kimberlite, as well as uncontrolled material, posed an ongoing challenge to the transfer system. Another challenge was how the conveyor received material from the grizzly underpan and jaw crusher discharge. The technical team from Weba Chute Systems assessed the challenges and, in partnership with the mine, engineered a material handling solution. The purpose-designed solution featured a transfer chute to better handle the 1,200 mm lump sizes. An integral swing mechanism reduces the impact on downstream components. The solution featured an engineered transfer point solution to enable co trolled fl ow through the grizzly underpan chute system. It also featured an upgrade to the crusher discharge chute. The chute has not required replacement since its installation over a year ago.

http://www.webachutes.com