2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

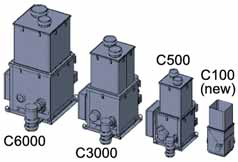

Schenck Process introduced the ProFlex C100 feeder. The smallest of the company’s C series, it is comparatively lightweight and fits on small extruders. Up to five feeders can be grouped around an inlet of a lab- or small-size extruder. The feeder is equipped with an integrated gearbox for turndown ratios of up to 1:120. It is NEMA drive-ready for compounding and masterbatch. The ProFlex C feeding system is characterized by asymmetric design, steep hopper walls, encapsulated cabling, ease of management, and ease of maintenance, the company reported.

More information at: http://www.schenckprocess.com