2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

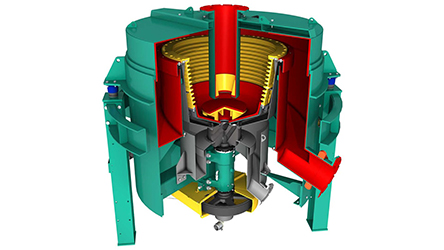

Long established in the gravity concentrator market Knelson presents their latest innovation in semi-continuous gravity separation, the Knelson GX Concentrating Cone.

Incorporating an advanced distribution of fluidisation water across the entire cone that allows for even distribution of water in each ring, facilitates not only the highest possible recovery of coarse and fine gold, the balanced water distribution also allows for a significant reduction in fluidisation water requirements. The third major benefit of the Knelson GX is easier maintenance. Because it is made of a customised, abrasion-resistant and durable polyurethane compound, maintenance frequency and operational costs are significantly reduced.

“The new Knelson GX Concentrating Cone is the culmination of over 40 years of research and operational experience and is exciting news for our customers: it delivers a win-win-win scenario: better recovery, less water use and less downtime due to easier maintenance. In short, it helps customers produce more with less resources – a central tenet of our MissionZero ambition to cut water and energy waste in mining by 2030,” comments Mike Lefler, Head of Global Product Line Manager for Precious Metal Recovery at FLSmidth.

For more information: https://www.flsmidth.com/en-gb/products/knelson-semi-continuous-gravity-concentrator?utm_campaign=Knelson-GX-concentrating-cone&utm_source=linkedin&utm_medium=social-post_flsmidth+mining&utm_content=183c2f78-1e99-485a-bfcc-3a8a98367e09