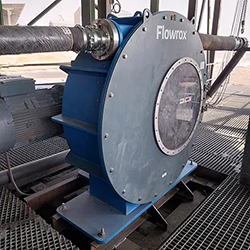

Valmet Boosts Mining Operations with Flowrox Pump

Valmet’s Flowrox™ peristaltic hose pump has significantly improved operational reliability and efficiency at an African copper mine. Facing frequent downtime and costly maintenance due to regular hose replacements in their existing slurry pumps, the mine trialled the Flowrox 360-degree DN100 pump designed for demanding slurry applications. The pump’s roller design reduces friction and heat, enabling continuous operation without overheating and eliminating the need for standby units.

Compared to the previous DN150 pump, the Flowrox model delivers higher flow rates at a smaller size, leading to improved energy efficiency and lower system costs. The pump handles slurries with up to 80% solids content and offers an extended hose lifetime of 1000 hours, along with reduced hose replacement time and lubricant use. These factors contribute to increased productivity and reduced operating expenses for the mining operation.

For more information

Categories: Pumps

2025-12-01 | Valmet Flow Control Oy | Finland | Views 56