Rhosonics and Flottweg Address Scaling Issues in Density Measurements

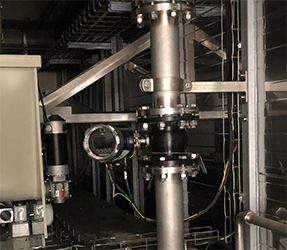

Rhosonics has collaborated with Flottweg to address challenges caused by scaling in industrial slurry pipelines. The issue, which affected density measurement reliability, has been resolved through a flush system integrated into Rhosonics' SDM sensor spool piece. This innovation enables daily cleaning without removing the sensor, ensuring consistent and accurate readings while reducing maintenance demands. A Pt100 sensor was also incorporated to monitor and compensate for temperature fluctuations in the slurry.

The solution has proven effective in restoring measurement accuracy, with density data now stable and varying by only 0.01 S.G. compared to manual readings. Following its successful implementation at a plant in Austria, the system is set to be deployed in a second location in Germany, further expanding its use.

“The flush spool in our last project is doing well. It is much better for the sensor with flushing, and the data is more stable.” said Christine Bauer-Salomon from Flottweg.

For more information

Categories: Instruments Monitors and Controls

2025-01-24 | Rhosonics | Netherlands | Views 579