UHT Uses Hägglunds Drive Systems for Converter Refining

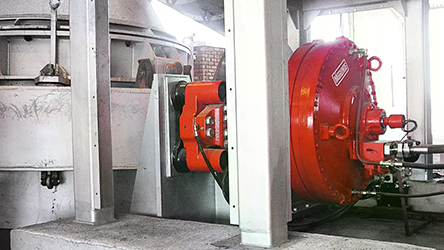

Swedish company Uvån Hagfors Teknologi AB (UHT), a supplier of metallurgical processes for steel, ferroalloy and stainless steel production, has integrated Hägglunds drive systems from Bosch Rexroth into its converter refining technology. UHT’s CLU® and AOD converter solutions both incorporate these hydraulic drives to support critical movements during charging, sampling and tapping of molten metal.

Hägglunds drive systems were selected to reduce vibration, improve control accuracy and lower maintenance demands compared to conventional mechanical drives. UHT says the systems deliver full torque from zero speed and allow for emergency power backup in case of outages, helping prevent costly process interruptions.

“Hägglunds drive systems provide full torque from the start, which allows our converters to tilt more quickly and precisely. This gives customers a clear advantage when aiming to reduce processing time and improve control during refining.” said Joakim Lundström, Sales and Procurement Director at UHT.

For more information

Categories: Drives

2025-06-23 | Bosch Rexroth - Sweden | Sweden | Views 443