All-Electric Kleemann Plant Train in Sweden

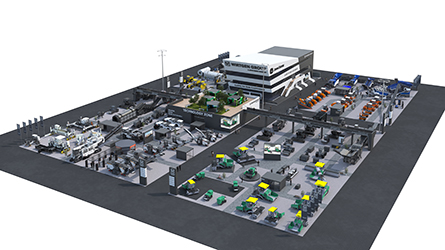

The Wirtgen Group’s Kleemann brand has supplied an all-electric plant train to Kentas Last & Schakt AB, located near Stockholm, Sweden. The train includes the jaw crusher MOBICAT MC 120 PRO, cone crusher MOBICONE MCO 110 PRO, and screening plant MOBISCREEN MSC 953 EVO, working together to process granite and recycling materials. This fully electric setup enables efficient handling of variable feed sizes while supporting one of Scandinavia’s first comprehensive electric crushing and screening operations. The machines communicate automatically to ensure smooth workflow and optimize production.

The decision to adopt an electric plant train was influenced by the desire to lower emissions and reduce operating costs. Kentas Last & Schakt AB invested significantly in site infrastructure, including a transformer station and underground cables, to enable this shift.

The electric operation also brings quieter machine function, faster startups, and around 50% lower energy expenses compared to diesel-powered alternatives. “We are actively working to convert as many machines as possible to electric power. This is clearly the way forward.” said Co-owner Freddie Erickson.

For more information

Categories:

2025-11-07 | Wirtgen | Germany | Views 10