Bunting Upgrade Industrial Magnetiser

To meet the increased demand for magnetic separators following a sustained period of sales growth, Bunting has redesigned and refurbished the industrial magnetiser at their Redditch manufacturing facility in the United Kingdom. The enhancements make this DC impulse industrial magnetiser the largest in the UK, outside of academia.

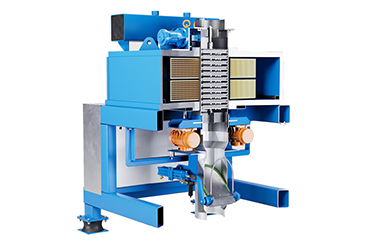

At the Redditch manufacturing operation, Bunting’s industrial magnetiser charges permanent magnet assemblies used in overband magnets, drum magnets, and pulley magnets. The magnet assemblies are built in an uncharged state and then placed within the magnetiser for charging to create a focused and specific shape of magnetic field. The nature of this created magnetic field dictates how the magnetic separator will separate ferrous metals and magnetically susceptible materials from non-metallic materials as in the recycling, mining, and quarrying sectors.

“Magnetising is a key stage within our manufacturing process and with the magnetiser refurbishment we are able to magnetise quicker and more efficiently than previously. The result is increased manufacturing capability and the ability to magnetise larger magnet assemblies. said Adrian Coleman, Bunting’s European Engineering Manager.

For more information

Categories: Magnets

2024-03-13 | Bunting - Redditch | United Kingdom | Views 1363