Bunting Develops High-intensity Electromagnetic Wet Filter

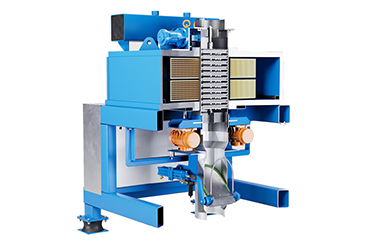

Bunting has introduced a new electromagnetic wet filter designed to separate fine iron and paramagnetic minerals from liquids and slurries. The system generates background magnetic fields of 3,500 to 10,000 Gauss and is used in applications including ceramics, mineral processing, and recycling. It also supports water treatment in industries such as steel production and power generation, addressing contamination issues in a range of processes.

The filter’s electromagnetic coil intensifies the magnetic field on the matrix surface, enhancing separation efficiency. Maintenance features include a built-in jig for safe handling and optional automation for managing the cleaning process. Energy-efficient coil designs ensure consistent performance while maintaining low operating temperatures.

Bunting says the filter addresses specific challenges in removing contaminants from liquids and slurries. “In ceramics, successfully removing any magnetic particle significantly reduces reject rates and rework costs. Having the ability to process non-metallic minerals in a wet state saves on drying costs and enables higher removal levels of magnetics.” said Adrian Coleman, European Technical Director.

For more information

Categories: Magnets

2024-11-26 | Bunting - Redditch | United Kingdom | Views 1000