TOMRA Mining Delivers Sorting Technology for World’s Largest Ore Sorting Plant

TOMRA Mining’s sensor-based sorting technology has been deployed at Pilbara Minerals' Pilgangoora Operation in Western Australia, marking the commissioning of the world’s largest lithium ore sorting facility. Integrated into the company’s P680 Expansion Project, the plant has a sorting capacity exceeding 1,000 tonnes per hour. TOMRA’s technology enables early waste removal, improving lithium recovery, enhancing product quality, and reducing energy consumption in downstream processes.

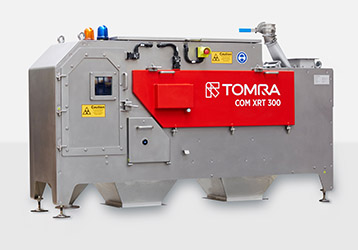

The facility, equipped with 10 TOMRA sorters for fine, medium, and coarse particles, was delivered on schedule in collaboration with Pilbara Minerals and engineering partner DRA Global. By removing barren material early in the process, the system reduces energy consumption by an estimated 8–15 GWh annually while maintaining consistent feed quality for downstream processing. This large-scale project highlights TOMRA’s ability to design and deliver innovative solutions for the mining industry.

“The success of this project is a testament to TOMRA Mining’s collaborative approach and capacity to deliver innovative, large-scale, high-capacity sorting solutions tailored to the unique demands of our clients, providing continuous support from the testing and design phases right through to installation, commissioning, and beyond,” said Gavin Rech, Area Sales and Technical Manager Australia at TOMRA Mining.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services Sorters - Mineral

2025-01-09 | TOMRA MINING | Germany | Views 801