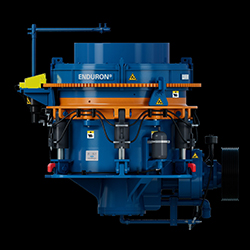

Weir Introduces New ENDURON® Crushers

Weir has launched a new generation of its ENDURON® jaw and cone crushers, designed in collaboration with customers to address operational, safety and sustainability challenges in mining. The updated range introduces redesigned hydraulic systems that enable push-button CSS adjustments and simplified installation, reducing manual handling and minimising environmental impact. By integrating ESCO® wear parts, the crushers also aim to extend service life and cut downtime, supporting more efficient and cost-effective operations.

The cone crusher models now feature a compact Hydraulic and Lubrication Power Unit, alongside an upgraded automation platform incorporating IO-link digital sensors and Siemens PLC hardware. According to Weir, this combination enhances reliability, simplifies servicing and allows seamless integration with site control systems. Together with existing ENDURON® screens and HPGRs, the new machines are part of a broader flowsheet approach to reduce energy consumption and boost productivity.

“We’ve listened closely to our customers and designed this range to meet their evolving needs. From safety and sustainability to ease of installation and maintenance, every feature is built to deliver real value on site.” said Magnus Skorvald, Global Product Manager – Crushers at Weir.

For more information

Categories: Crusher - Parts Crushers

2025-10-01 | Weir | United Kingdom | Views 538