Tenova to Supply Walking Beam Furnace to Salzgitter Flachstahl

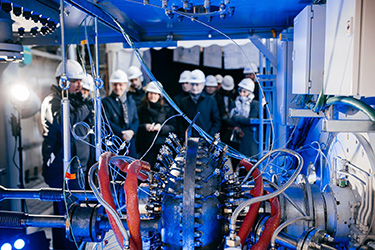

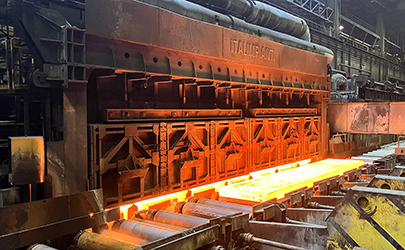

Salzgitter Flachstahl GmbH has awarded Tenova a contract to supply a walking beam furnace for its site in Salzgitter, Germany. The furnace is designed to improve energy efficiency and support Salzgitter Flachstahl’s decarbonization objectives. The order includes a fully integrated system comprising the furnace, handling equipment, and associated control and electrical systems.

Tenova says the 320 t/h furnace will be equipped with hydrogen burners, oxygen injection zones, and a combustion air pre-heating system to reduce energy use and emissions. A heat recovery system will also be installed to generate steam from waste heat for use across the plant. This is the third walking beam furnace supplied by Tenova Italimpianti to the Salzgitter site.

"We are proud to strengthen our collaboration with one of Germany’s leading steel producers, supporting their goals for energy efficiency and sustainable production. This project reinforces Tenova’s leadership in the field of energy-efficient and low-emission reheating solutions, paving the way for further technological advancements in the steel industry.” said Antonio Catalano, EVP Downstream Business Unit at Tenova.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2025-06-24 | Tenova | Italy | Views 438