Multotec PU Mats Deliver Cost Savings for Mining Operation

A South African rock and mineral mine has reported significant cost savings and operational improvements following the introduction of Multotec’s side-tension polyurethane (PU) screening mats. The mine had previously relied on woven wire mesh in its secondary sizing plant, but frequent change-outs due to wear and tear created high maintenance costs, increased downtime, and elevated safety risks for workers.

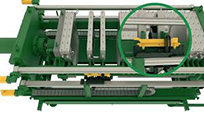

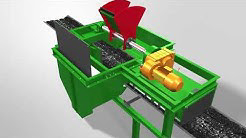

The transition to PU mats provided a longer-lasting screening solution that could be installed on existing vibrating screens without structural changes. Designed for durability and ease of installation, the custom hand-cast mats have demonstrated resilience in demanding conditions and are already applied across a range of commodities, including coal, gold, limestone, and platinum group metals.

“In this case, the woven wire mesh struggled to withstand the impact and abrasion from the product stream, necessitating frequent change-outs—sometimes as often as twice a month. This led to high maintenance costs due to frequent purchases of new mesh; interruptions in production during change-outs; and increased labour hours and associated health and safety risks,” said Pieter Uys, Business Development Manager at Multotec.

For more information

Categories: Screens - Mats & Plates

2025-09-19 | Multotec | South Africa | Views 650