Metso Introduces Cu POX Leaching for Copper Recovery

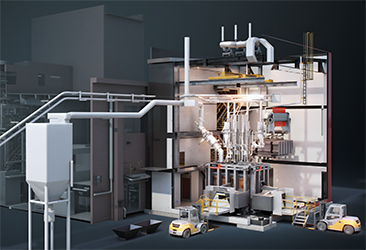

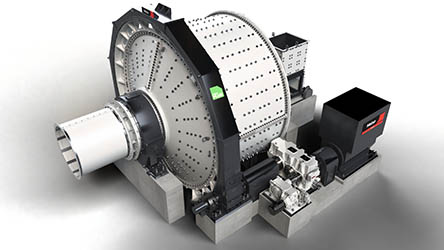

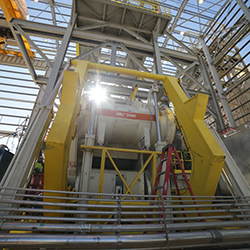

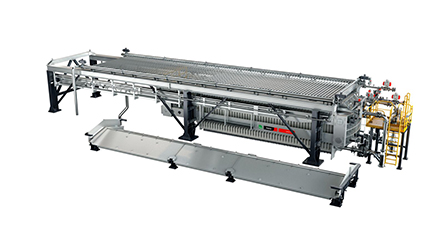

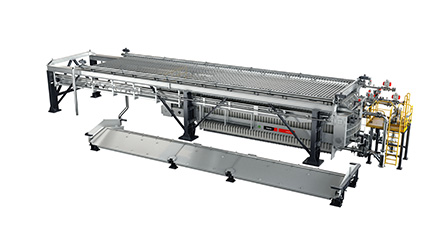

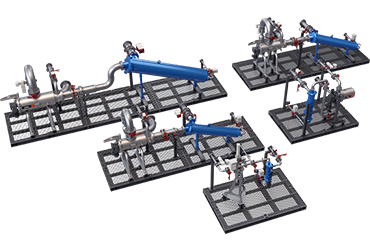

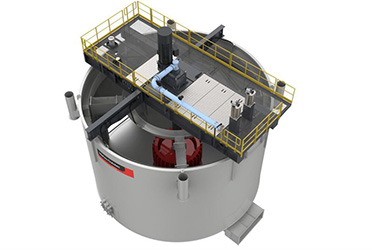

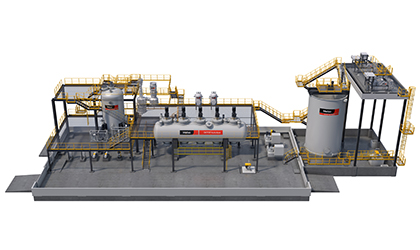

Metso has launched its Cu POX leaching process, designed to extract copper from sulfide concentrates while reducing environmental impact. The hydrometallurgical process uses Metso’s OKTOP® Autoclave unit to oxidize copper concentrate under high pressure and temperature, producing a copper-bearing solution for solvent extraction and electrowinning. The company says that this method ensures high copper recovery and integrates with existing SX-EW infrastructure.

According to Metso, the Cu POX process is scalable and adaptable to different raw materials. It can also enhance existing heap leaching operations by maintaining PLS production as deposits decline. The company offers a full suite of services, from testing and engineering to plant commissioning and ongoing support, to optimize performance.

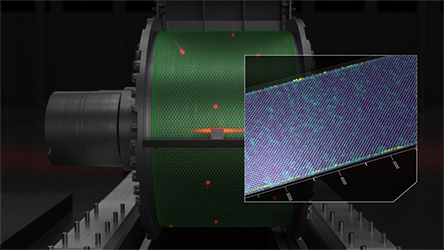

“Copper sulfide minerals require specialized leaching conditions to achieve high recovery rates. Metso’s Cu POX leaching utilizes high-temperature oxidation to convert sulfide sulfur into sulfate and sulfuric acid, ensuring efficient copper dissolution,” said Petteri Pesonen, Technology Manager, Copper Hydrometallurgy at Metso.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2025-03-13 | Metso Corporation | Finland | Views 776