Metso Technology Backs Australian DRI Project

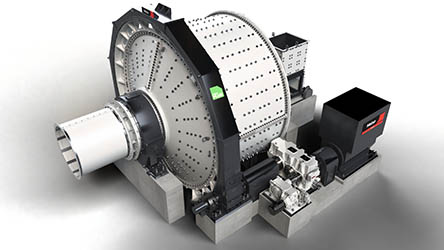

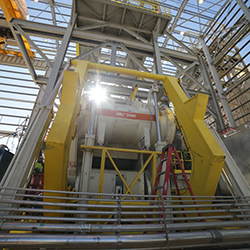

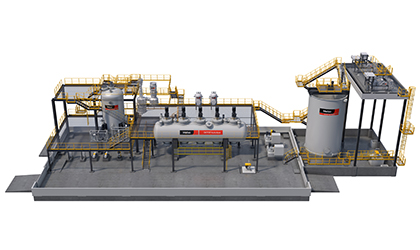

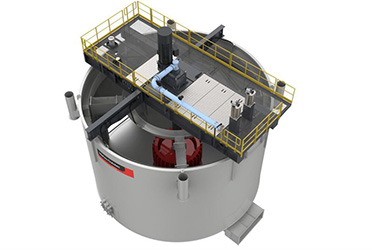

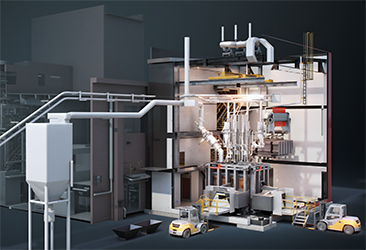

Metso is providing the core process design and technology for Fortescue’s Christmas Creek Green Metal Project in Western Australia, where installation of Metso equipment began in September 2025. The development is intended to showcase production of high-purity green metal using renewable energy and hydrogen-based reduction. Central to the project are Metso’s Circored™ fluidized bed direct reduction process and its electric DRI Smelting Furnace, both positioned as low-emission solutions for future steelmaking.

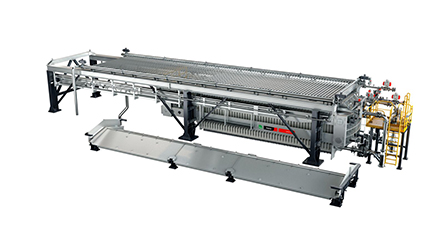

The project’s initial phase targets an annual output of more than 1,500 metric tons, with studies underway to evaluate a commercial-scale facility. Metso highlights the Circored™ process as a fine-ore, fluid-bed system that operates solely with green hydrogen, removing the need for pelletization. According to the company, this allows the production of highly metalized DRI suitable for direct use in electric smelting furnaces, a route designed to support lower-carbon steel production.

“This project, which implements the Circored™ and DRI smelting solutions, underscores our commitment to advancing sustainable and efficient industrial processes. The Circored™ process uses solely green hydrogen instead of fossil reductants.” said Attaul Ahmad, Vice President, Ferrous and Heat Transfer at Metso.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2025-11-19 | Metso Corporation | Finland | Views 60