Metso Announces Updates to Copper Electrorefining Technology

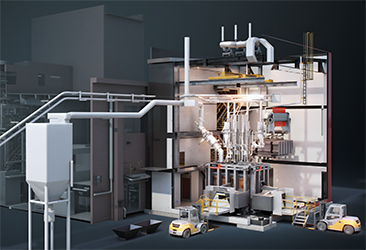

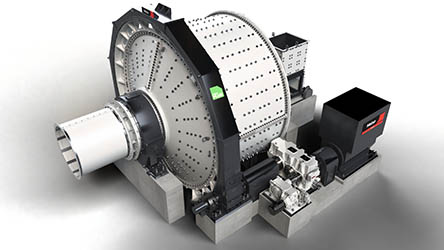

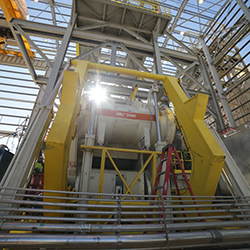

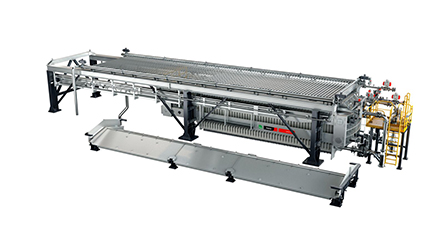

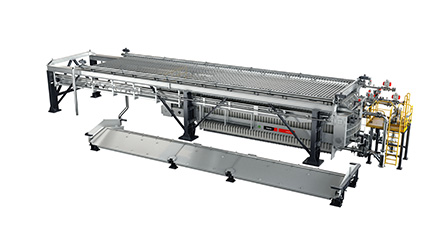

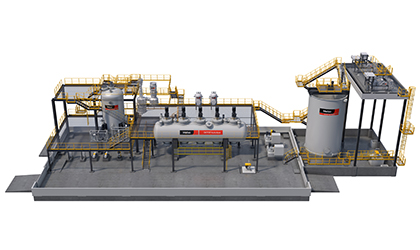

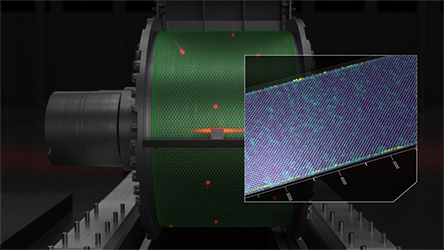

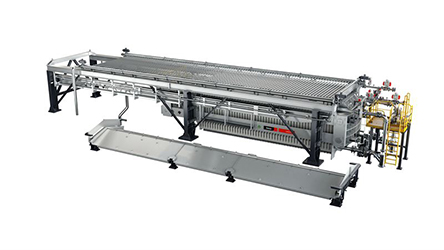

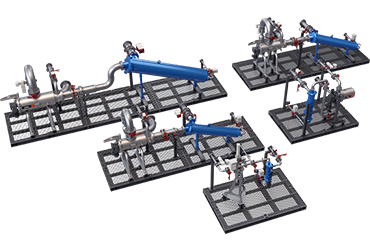

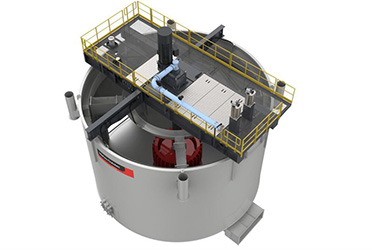

Metso has introduced enhancements to its copper electrorefining technology, which the company says support the production of high-purity LME grade A copper cathodes. The updated offering is designed to deliver a seamless material flow and minimize total cost of ownership, with an integrated approach that combines machinery, modular layouts, digital solutions and lifecycle service support. Electrorefining is used in the production of over 80% of the world’s copper and is valued for both purity and the recovery of by-products.

The company’s electrorefining solutions include proprietary equipment under the Outotec® and OKTOP® brands, along with process control systems and material handling technologies. Metso says these are suitable for new and existing operations and are designed to improve operational reliability, product quality and safety. Spare parts, upgrade options and access to the company’s global service network are also part of the package.

“No two refineries are the same – that’s why our solutions are designed to be modular and flexible, while still ensuring the highest performance and safety,” said Noora Aro-Koivisto, Copper Electrorefinery Technology Manager at Metso.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2025-06-18 | Metso Corporation | Finland | Views 692