Metso Launches Advanced OKTOP Cooling Tower

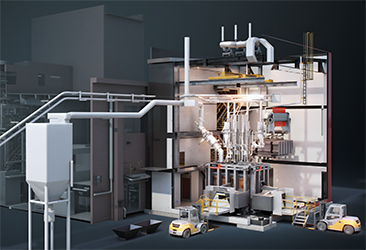

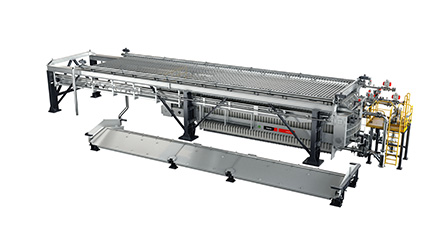

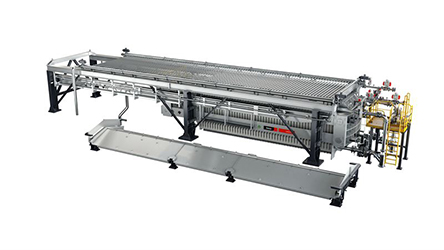

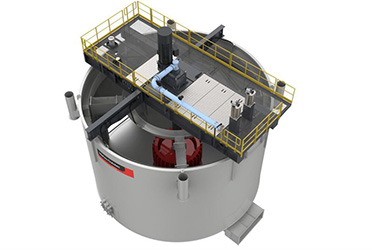

Metso has introduced the third-generation OKTOP® Cooling Tower, designed to meet the demanding requirements of slurry and electrolyte cooling in metals refining. The new model features a compact footprint, making it well suited for brownfield sites, and offers simplified design for faster installation and easier maintenance. It also boasts low emissions, aligning with Metso’s commitment to sustainable operations.

The OKTOP Cooling Tower improves cooling efficiency by reducing the recirculation of warm off gas and is noted as the first self-cleaning cooling tower in the market, extending operational intervals. This solution is part of the Metso Plus offering, which includes a range of hydrometallurgical processing technologies aimed at optimising metallurgical performance and operational reliability.

“The third-generation OKTOP Cooling Tower is designed for maximum efficiency and minimized downtime and maintenance costs. It offers an installation footprint that is up to 70% smaller while maintaining superior cooling power compared to the previous generation,” said Valter Mangs, Product Manager for Cooling Towers at Metso.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2025-12-03 | Metso Corporation | Finland | Views 44