Sandvik Adds Pumpable Resin System for Bolters

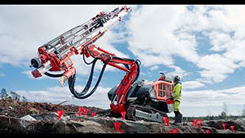

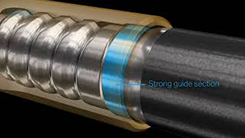

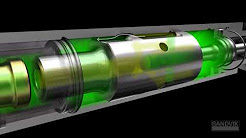

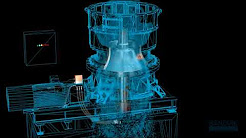

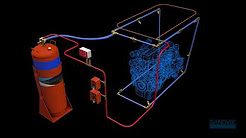

Sandvik Mining has introduced a pumpable resin system for its DS412i and DS412iE underground drill rigs. The system supports both self-drilling bolts (SDB) and hollow bar bolts (HBB) and is designed to work with Sandvik’s ground support tools, including the DSI Hollow Bar System and Mineral Bolt resin. Sandvik says the fully sealed unit removes the need for manual chemical handling and enables one-bolt automation for efficient, consistent installation in difficult ground.

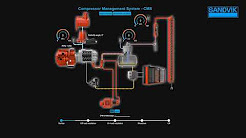

The company adds that the system automatically controls the resin mixing and filling process, only dispensing the required volume per hole. It also highlights reduced downtime due to a larger onboard resin capacity and faster re-entry made possible by the Mineral Bolt’s adjustable curing times. The system is also available for Sandvik’s DS512i rig as a custom order.

Sandvik’s Ground Support team offers pull-out testing services to support quality control during bolting cycles.

Categories: Bolts Drill - Rigs Tunnelling - Equipment

2025-06-23 | Sandvik Mining and Rock Solutions | Sweden | Views 16