Sumitomo Metal Mining’s Hishikari mine automates with Sandvik

Sumitomo Metal Mining’s Hishikari mine automates with Sandvik

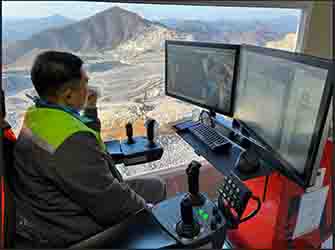

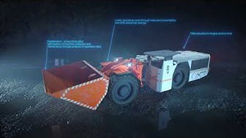

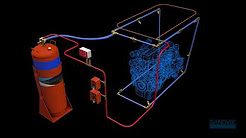

Sumitomo Metal Mining Co., Ltd.’s Hishikari mine is the first Japanese underground mine utilizing automated loading technology from Sandvik. AutoMine® will help enable increased productivity, improve safety and better cost control, while bringing digital transformation of the mining process closer and increasing operational transparency.

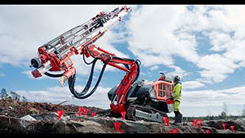

Located in northern Kagoshima Prefecture, the Hishikari mine, boasts a high grade of around 20 grams of gold per tonne of ore and has been producing gold steadily since 1985. The only gold mine in Japan that still operating on a commercial, they commissioned AutoMine® Lite on a Toro™ LH307 underground loader in December 2022 to operate in its small cross-section tunnels and utilize the system in production areas to enhance safety, accelerate underground efficiency and improve productivity.

“Sandvik did a great job commissioning and training our engineers and operators on the AutoMine® system,” said Hidenobu Yabu, Manager of Mining Section for the Hishikari mine. “Our goal is to become a corporate enterprise that produces resources with advanced technology by 2030. By implementing advanced technology and innovation, we aim to reduce costs, increase productivity and improve safety. Our commitment to sustainability is reflected in our long-term focus on the Hishikari mine.”

“We are excited to partner with the Hishikari mine on this project and look forward to contributing to the operation’s sustainability and productivity,” said Jan-Douwe Wansink, Business Line Manager Automation for Sales Area Southeast Asia at Sandvik Mining and Rock Solutions. “AutoMine® provides a safe, controlled environment that boosts productivity and profitability while helping to protect operators and other mine personnel in underground operations. This is an exciting opportunity for the Hishikari Mine and Sandvik.”

For more information

Categories: Autonomous Systems Autonomous Vehicles Load Haul Dump Vehicles Loaders - Underground

2023-02-06 | Sandvik Mining and Rock Solutions | Sweden | Views 2712