Sandvik Expands Electric Crushing and Screening Line

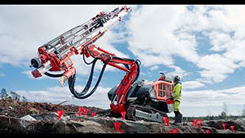

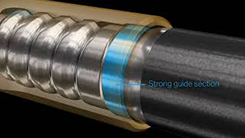

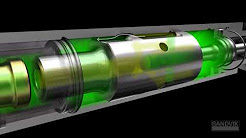

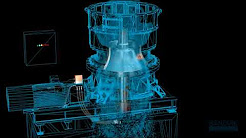

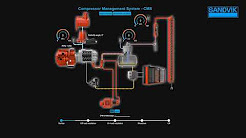

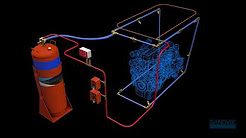

Sandvik Mobile Crushing and Screening has introduced the QH443E, an electric-driven tracked cone crusher, as the latest addition to its fully electric crushing and screening train. Designed for secondary and tertiary crushing in quarries, mines, and aggregate production, the QH443E integrates an electric drivetrain with tracked mobility. It features the CH440 Hydrocone crusher, Optik™ automation, and My Fleet remote monitoring, offering fuel savings and reduced oil consumption compared to previous models. The unit can operate via its onboard genset or an external power source, minimizing onsite emissions and running costs.

The QH443E joins the UJ443E fully electric jaw crusher and the QA452e hybrid Doublescreen, forming Sandvik’s electric train for more efficient material processing. The UJ443E incorporates the CJ412 jaw crusher and a new fully electric track platform, while the QA452e’s hybrid drive enhances energy efficiency. Sandvik says that the system allows for reduced fuel consumption, lower maintenance requirements, and streamlined operation by powering downstream equipment from a single source.

“Completing the development of our tracked electric train marks a significant step towards a more sustainable and cost-effective future for the crushing and screening industry. This is just the beginning of our commitment to developing solutions that improve the productivity, safety, and sustainability of our customers' operations.” said Manny Maloney, President, Sandvik Mobile Crushing and Screening Division.

For more information

Categories: BEV - Battery Electric Vehicles Crusher - Mobile Crushers

2025-03-25 | Sandvik Mining and Rock Solutions | Sweden | Views 729