Sandvik - AutoMine® Flexible Safety Zone

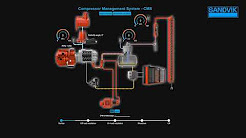

Sandvik Mining and Rock Solutions is introducing AutoMine® Flexible Safety Zone, a new feature for its AutoMine® underground system for autonomous mining operations. The new capability is designed to improve productivity and increase flexibility by enabling alternating safety zone states between autonomous and manual operation.

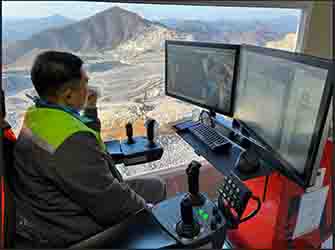

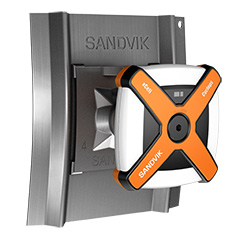

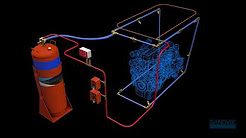

With the AutoMine® Flexible Safety Zone, autonomous mining equipment can operate continuously in the automated area while allowing for intersections with manual equipment. This capability makes it possible for manual equipment to cross automated equipment routes and share dump or load points. In addition, AutoMine® access barriers are equipped with state-of-the-art technology that informs operators of the shared area status with visual and audible state indications.

“Our new technology will increase the flexibility between manual and automated equipment by allowing manual operators to request access to a shared area. This request is designed to prevent automated equipment from entering the shared area while manual equipment occupies it. In addition, this flexibility will further enhance customer productivity and allow for continuous operation of both automated and manual equipment,” said Jouni Koppanen, Product Line Manager Automation, Sandvik Mining and Rock Solutions.

Manual operators can request access to a shared area using a variety of actuators at the access barriers. Once acknowledged by the Supervisory AutoMine® System and autonomous vehicles have cleared the area, access is granted, and manual vehicles can enter safely. This procedure ensures the safety of all operators and equipment while allowing for more flexible setups.

“This new feature will enhance our customers’ AutoMine®. We are giving operators the tools they need to adapt to changing conditions, which will ultimately improve productivity and safety in their mines,” said Elen Toodu, Director Global Product Line and Projects Automation, Sandvik Mining and Rock Solutions.

For more information

Categories: Autonomous Systems Autonomous Vehicles Load Haul Dump Vehicles

2023-05-08 | Sandvik Mining and Rock Solutions | Sweden | Views 2332