Advancing Autonomous Surface Mining - Q&A with Epiroc’s Mayya Popova, Product Manager Automation.

In our recent interview, Mayya shared some insights into the company’s autonomous mining solutions and their impact on surface mining operations.

Q. What are Epiroc’s current offerings in autonomous mining?

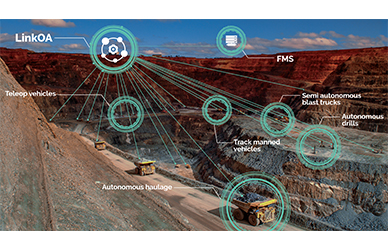

A. Epiroc’s portfolio includes advanced drill rigs such as the Pit Viper Autonomous and SmartROC D65 Autonomous, complemented by integrated control room systems and digital platforms designed to streamline workflows and boost productivity. In addition to drilling, Epiroc offers autonomous haulage solutions through LinkOA for Haulage, providing autonomous control of haul trucks to improve safety, efficiency, and productivity. We also work closely with our acquired firms, such as RCT, to deliver smart technology solutions across other areas of mining operations.

Q. How are your autonomy solutions helping customers improve safety, productivity, and sustainability?

A. Safety and sustainability are core benefits of Epiroc’s technologies. By relocating operators to remote control rooms, exposure to hazards like dust and noise is significantly reduced. This setup also enables a single operator to control multiple machines simultaneously, decreasing downtime, cutting operational costs, and reducing carbon footprints by minimizing on-site personnel travel.

Q. Could you share an example of a mine currently using Epiroc’s autonomous solutions?

A. Our autonomous systems have seen wide global deployment, with over 150 autonomous Pit Viper rigs currently in operation. Notable examples include Fortescue’s autonomous SmartROC D65 fleet and Luck Stone’s fully autonomous SmartROC D65 rig in the U.S. market. This year marks a significant milestone — the Pit Viper drill is celebrating its 25th anniversary. For over a quarter of a century, it has set the standard for surface drilling, with the last ten years showcasing its evolution into autonomous technology.

Q. What role does interoperability play in Epiroc’s approach to autonomy, particularly in mixed-fleet operations?

A. Epiroc’s solutions are designed to integrate seamlessly within mixed equipment fleets via an agnostic platform and smart technology. Collaborations such as the partnership with Hancock Iron Ore at Roy Hill highlights the company’s commitment to flexible, multi-vendor autonomous mining solutions.

Q. Looking ahead, what technologies or innovations do you believe will deliver the biggest changes in autonomous mining?

A. Epiroc continues to prioritize electrification and ongoing automation innovation, backed by an active development pipeline. We work closely and learn from collaborations with strategic industry partners and academic institutions worldwide to accelerate transformation and leverage extensive expertise, propelling our products to the forefront of technology. This approach aims to advance autonomous mining technologies that meet industry productivity targets and environmental sustainability goals.

Q. Are there any upcoming product launches, partnerships, or pilot projects that you can share with us?

A. There are always new developments underway as part of a continuous pipeline of product improvements. Epiroc’s approach emphasizes collaboration with trusted business partners who help validate and support each innovation. This partnership-driven process allows for refining solutions before they are officially released to the market, ensuring they meet customer needs effectively.

For more information

Categories: Autonomous Systems Autonomous Vehicles Drilling - Equipment and Supplies

2025-11-19 | Epiroc | Sweden | Views 316